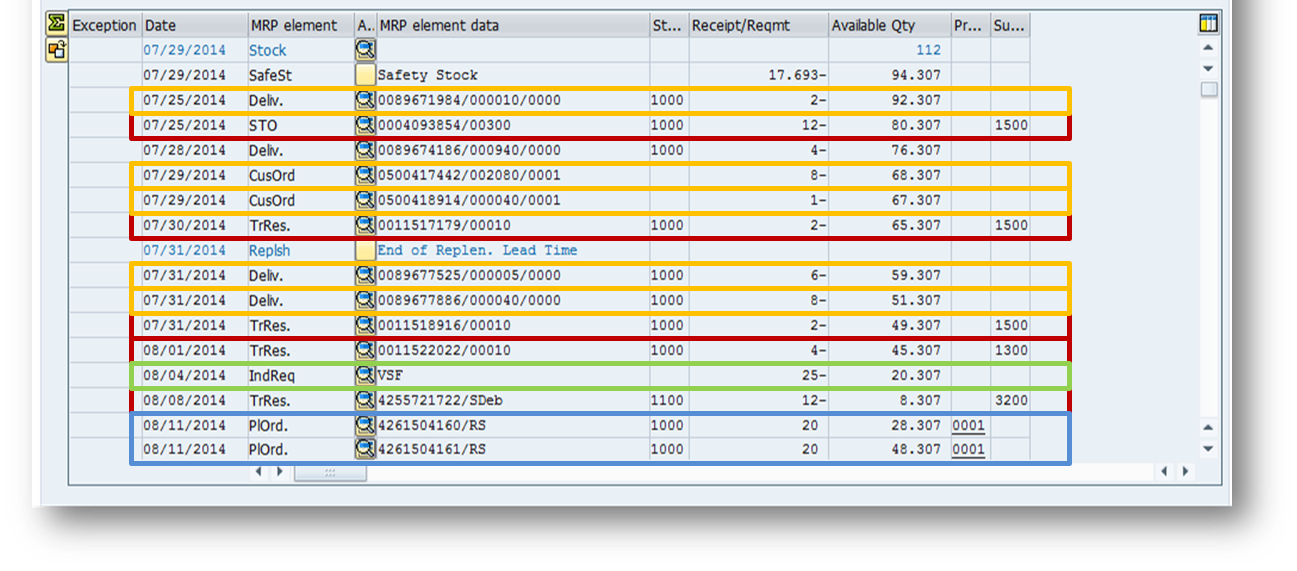

What usually happens then, is that every materials planner figures out how much inventory they need to hold and what replenishment policy to use to achieve that. If you want to standardize this kind of directive and develop a system to have everybody use the same calculation, I suggest you use the field 'service level' in MRP2 and calculate the safety stock setting for each material using the variables lead time, mean absolute deviation and a safety factor.

You can do this on the forecasting screen of the material master. Depending on how you configured your MRP type, the forecast run can calculate safety stock level for you. However, you have to kind of doing this for every material and you can only simulate exactly one service level.

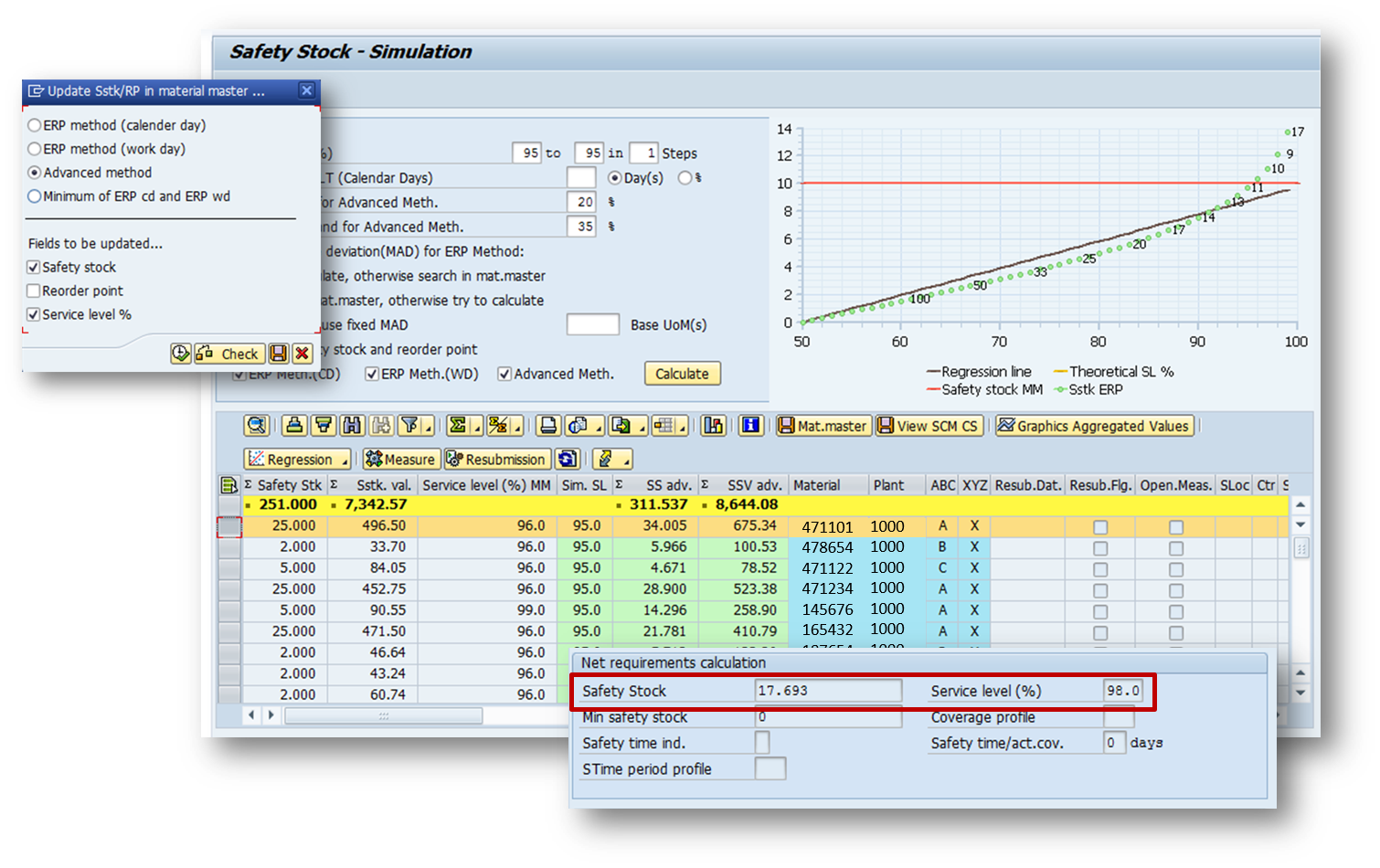

A better solution is the SAP Add-On Tool 'Safety Stock and Reorder Point Simulator'. With it you;re also getting a new KPI: safety stock value! You can also simulate many service levels and compare the results in terms of quantity and value. On top of everything else, the safety stock calculation gives you two more - very important - parameters: the variation in replenishment lead time and a variation in demand.

Let's say management desires a service level to the customer of 95%. In that case you would pull all those materials into the simulator, set 95% nd your variation in lead time demand and click the 'calculate button. The simulator then calculates all safety stock individually for each materials and totals the value. This way you can determine what a 95% service levels means compared to your current master data settings or to other service levels. In our example, all materials currently have a service level of 96% which, with the manual calculation the materials planner was using, produced a value of $7,342 in safety stocks. However, the safty stock simulator produces a value that's higher with a lesser service level... and that calculation is using the same variables for each material across the board and therefore probably much more accurate than what the planner ever can come up with - possibly applying different methods and being totally overwhelmed doing this for hundreds, if not thousands of materials.

In the end, you push the save button and safety stock and service level are being updated into the MRP2 screen for each and every material in the list.

Management changes their mind tomorrow? no problem!