As I am just coming back from Germany, I can't deny that a book, given by my good friend Ulli Nagel has made a very profound impact on me. No wonder... The book was written by Heinrich Hansjakob, a fellow who lived over 100 years ago in the same area of the Black Forest where I was growing up. And 'Der Vogt auf Muehlstein' takes place just uphill from the house I was born; some 200 years removed.

The Muehlstein is a farmer's house overseeing the valleys of Nordrach and Harmersbach and looks all the way out to Strasbourg in France on a good day. It houses a Wirtsstube where many hikers and locals visit and have delicious Speck, sausages and Schnaps in the old 'Stub' (the living room) of the last inhabitant Josef Erdrich. Sadly the "Erdrich Sepp" died two month ago.

Everybody in my hometown and the surrounding villages was shaken by the news. What will happen to one of the most traditional estates the Black Forest ever had? Its history is long and rich and author Heinrich Hansjakob (a pastor in the days of the late 19th century) captured its essence beautifully by retelling the true story of Anna Maria Magdalena Muser, the only daughter of the Bailiff of Muehlstein.

All characters had actually lived and as tragic and sad the story is, as beautifully Heinrich Hansjakob stays true to giving us a wonderful insight into the characters and lives of my ancestors in the last three decades of the 18th century.

For those of you who speak German, I urge you to order the book on www.amazon.de. It's a story that will move you. To those who don't understand us, you will have to be content with my recap... but only until I find someone in New York who will make a movie out of this!

And here the story (very short version) goes as much as I can retell it in English...

Magdalene is the fifth child and only daughter of the bailiff of Muehlstein and grows up happy and protected in the 1770s and '80s. She is the most beautiful girl of all the valleys and hills around. Singing was as common in those days in the Black Forest as watching television is today. And Magdalene could sing like a nightingale. Every Sunday the folk would come down to the valley for mass and during spring, summer and fall there were fairs, weddings and festivities all around. In Nordrach, Zell and Entersbach there were many occasions where young folk would meet and sing together. And Magdalene was the best. Especially with the Oelerjok's Hans. When the two performed together, it was like heaven came to earth.

As it turned out the two were also developing a liking for each other but because Hans was the 'middle' son and therefore would never inherit a property, it was clear that there was no future for the two. In those days in the Black Forest you would not marry for love but for protection and support. And every father wanted to marry his daughter into a protected livelihood.

And so it turned out that the 'Hermesbur' Faisst lost his second wife and was on the lookout for another. 53 years of age (Magdalene was 19) and the wealthiest farmer around, he asked the bailiff for the hand of his daughter. Everybody knew of Magdalenes love to Hans but the rules were also very clear: you don't marry for attraction and you do what your father considers best for you..

So it was a no brainer for the Muser Toni to promise his daughter to the old, fat man. But Magdalene refused at first. She just could not give herself up to someone she did not like. Her struggle, however, was impossible to succeed and on January 17, 1785 she was married to the Hermesbur. The wedding celebrations were a last, desperate but hopeless attempt, as Hans showed up singing an ode to his beloved Magdalene. The sad bride herself returned the treat with her own love song to Hans, which she had sung to herself over the past 6 months in despair and desperation. Even her cold hear-ted father and the somewhat simple Hermesbur couldn't hide their emotions. But that night, Magdalene moved in with her new husband and Hans packed his few possessions and left his hometown to never return.

After a few days of stoic reluctance by Magdalene, the Hermesbur threatened to take his wife by force. But Magdalene stood up to the overbearing figure and told him that... "I will be your working mate for the rest of my life, but I will never be your wife." Her willpower was countered with a beating, first by her new husband and later, by her father. Only two months after the wedding, on March 18th 1785, Magdalene died and was buried in Zell under the watch of her remorseful father and an indifferent husband who got remarried only 6 weeks after his third wife's death. He subsequently had another 11 children.

Hans, meanwhile was fighting as a mercenary in France and Austria, unaware of the tragedy that happened to the only woman he ever loved. Years later his younger brother met him by chance at a battle in the Alsace and told him what happened. Hans asked for an 18 hour leave, rode to Zell and visited Magdalene's grave. Without visiting his family, he immediately returned to the fighting front and died in battle the next day.

Magdalenes father, the bailiff of Muehlstein, fell in the winter of 1780 - exactly five years after Magdalenes death - and froze to a miserable death overnight. (My retelling here does absolutely no justice to Heinrich Hansjakob. If you get a chance, read the book and you will be taken by the rich character descriptions and you can gain a glimpse of the interesting lives of the people of the late 18th century Black Forest)

Today, Magdalenes grave is still maintained by the city of Zell, my hometown. And the Muehlstein house still stands. However, since we now miss the Erdrich Sepp, no one knows if we can ever walk up the mountain again, to relive our past with a traditional meal (Vesper) and Most and Schnaps in the Stube on the Muehlstein.

Time will tell, but until then, I will put that book into my shelf in New York City and know for sure that it helps me to never forget where I am coming from.

SAP Mentor, supply chain management enthusiast. Advocate for science as a basis to optimize the SAP supply chain. Active in Europe and North America. Sailboater, private pilot, motorbiker. At home in Tribeca, NYC. The opinions expressed in this blog are mine!

Sunday, December 30, 2012

Saturday, December 29, 2012

sexy SAP analytics

Just recently I read a comment from a fellow consultant on Twitter. He is mocking his client about their statement that the SAP LIS graphics are not sexy. "I suspect these managers should rather be focusing on the gruesomeness of their inventory levels, rather than “sexiness” of the SAP graphics!", he continues his judgmental ranting.

Really?, I am asking. Is that your idea of using the world's best operations management system? Doing analysis with graphics that look like Keith Richards would have used them in his early school years?

Really?, I am asking. Is that your idea of using the world's best operations management system? Doing analysis with graphics that look like Keith Richards would have used them in his early school years?

I am sorry, but I have to sympathize with the client. They are absolutely right to ask for a better tool and it is our (the consultants) responsibility to improve on the tools that our clients use. And yes: those tools should have some "sexiness" too! After all we are living in a new world (remember, the Mayan calendar has ended) and one of the important aptitudes of the new age is 'design'! (see my blog about Daniel Pink's Six Aptitudes). There are many better ways to analyze with standard SAP tools and beyond (I have written a number of blogs on the subject and will continue to do so).

In the end it comes down to what our job as a consultant is. It certainly is not to mock the client about wanting the best there is (I should note that the mocker himself ONLY knows the LIS from all the functions in SAP and therefore I understand his defense - but I do not support it). We consultants get around and we see many things. The good ones learn something new every day and aren't afraid to share it widely. The bad ones stick with what they know and mock any progress and the slightest possibility that what was good yesterday might not be so good (for our clients) today.

...and what's wrong with some sexiness in our otherwise prude subject matter?

In the end it comes down to what our job as a consultant is. It certainly is not to mock the client about wanting the best there is (I should note that the mocker himself ONLY knows the LIS from all the functions in SAP and therefore I understand his defense - but I do not support it). We consultants get around and we see many things. The good ones learn something new every day and aren't afraid to share it widely. The bad ones stick with what they know and mock any progress and the slightest possibility that what was good yesterday might not be so good (for our clients) today.

...and what's wrong with some sexiness in our otherwise prude subject matter?

Wednesday, December 26, 2012

Metaphysics and the SAP supply chain?

When Aristotle took on Metaphysics he wrote about four causes with which an object can be explained; material, efficient, formal and final. A material cause is the stuff a thing or system is made of, the efficient cause is the thing which made it or changes it. The formal cause, and now it gets interesting, is the system's essence or arrangement and the final cause is the purpose of the thing or system.

Now, if operations management with (or without) SAP underlies the still irrefutable laws of metaphysics, then I want to ask the question about how much of the formal and final causes we care about in our efforts to run and continuously improve supply chains. Obviously we do care a lot about the material and efficient causes. As a consequence we pay a lot of attention to the study of business process and product development, but underlying business dynamics and purposeful outcomes fall through the cracks.

All too often we can see slogans, buzzwords, 'philosophies' and entire movements with little or no final or formal goal orientation. Speaking of the goal: Eliyah Goldratt had formulated a final cause with his book 'The Goal' almost 30 years ago. His interpretation of The Goal for a manufacturing operations system (our final cause here) was: "to make money now and in the future". Wallace and Hopp updated this essential purpose by adding "...in ways that are consistent with our core values" in their book 'Factory Physics'.

Once we consider the final cause in our operations management system, we need a way to get there. This is where the formal cause comes into play. The formal cause of a manufacturing operations system is its structure; its underlying principles, governing laws; its essential 'form'. When constructed the right way, it provides a framework of reference, a scientific basis, a guiding model with which policies may be simulated so that we can anticipate what steps need to be taken to achieve The Goal.

Maybe we can now agree that any improvement or change efforts guided by material and effective causes only, may be exclusively driven by experience and guesswork. Once we are adding the final cause to have a purpose to work towards to and a formal cause with a model, where we can practice and simulate policies... then we can develop intuition, anticipate results, measure progress and generally move into a better world.

So please allow me at this point to add my own little 'philosophic' part so that we could say: "...the final cause or essential purpose of a manufacturing operations management system is to make money now and in the future in ways that are consistent with our core values and...the formal cause or scientific basis of a manufacturing operations management system provides us the framework to construct policies to achieve the final cause"

In that sense it might be worthwhile to consider - next to material and effective causes - a well defined goal and employ a scientific approach in any business improvement program. Easier said than done... but what's the alternative? eliminate muda? that's like saying "I want to be a better cook" and does not provide any guidelines or goals on how good you want to become or how you can get there.

Now, if operations management with (or without) SAP underlies the still irrefutable laws of metaphysics, then I want to ask the question about how much of the formal and final causes we care about in our efforts to run and continuously improve supply chains. Obviously we do care a lot about the material and efficient causes. As a consequence we pay a lot of attention to the study of business process and product development, but underlying business dynamics and purposeful outcomes fall through the cracks.

All too often we can see slogans, buzzwords, 'philosophies' and entire movements with little or no final or formal goal orientation. Speaking of the goal: Eliyah Goldratt had formulated a final cause with his book 'The Goal' almost 30 years ago. His interpretation of The Goal for a manufacturing operations system (our final cause here) was: "to make money now and in the future". Wallace and Hopp updated this essential purpose by adding "...in ways that are consistent with our core values" in their book 'Factory Physics'.

Once we consider the final cause in our operations management system, we need a way to get there. This is where the formal cause comes into play. The formal cause of a manufacturing operations system is its structure; its underlying principles, governing laws; its essential 'form'. When constructed the right way, it provides a framework of reference, a scientific basis, a guiding model with which policies may be simulated so that we can anticipate what steps need to be taken to achieve The Goal.

Maybe we can now agree that any improvement or change efforts guided by material and effective causes only, may be exclusively driven by experience and guesswork. Once we are adding the final cause to have a purpose to work towards to and a formal cause with a model, where we can practice and simulate policies... then we can develop intuition, anticipate results, measure progress and generally move into a better world.

So please allow me at this point to add my own little 'philosophic' part so that we could say: "...the final cause or essential purpose of a manufacturing operations management system is to make money now and in the future in ways that are consistent with our core values and...the formal cause or scientific basis of a manufacturing operations management system provides us the framework to construct policies to achieve the final cause"

In that sense it might be worthwhile to consider - next to material and effective causes - a well defined goal and employ a scientific approach in any business improvement program. Easier said than done... but what's the alternative? eliminate muda? that's like saying "I want to be a better cook" and does not provide any guidelines or goals on how good you want to become or how you can get there.

Sunday, December 9, 2012

S&OP can be done using ERP only. But! It's very dangerous if your adviser does not know APO

There are people talking at SAP supply chain conferences about how Sales & Operations Planning is playing the most important role in your planning process. I do believe it is important and a good plan for the right product can save you money in inventory holdings and make your customers happy with great service levels and fill rates. It can also reduce noise in the supply chain and, with a good forecast, provide a great tool to anticipate demand and therefore inventory holdings of finished goods, help with decision making in regards to the resources you need to make available and allow you to simulate various version and effects of a corporate supply chain strategy.

The question is how do you get to a good plan in S&OP. For those of you whose company has purchased SAP software, the speaker should lay out good practices (if not the best) and give you valuable insight on how to best use that tool - SAP. And as we all know SAP software is comprised of an S&OP tool in its ERP version but they also sell advanced planning tools with APO. Now, if you get an adviser who tells you to use ERP or another one who tells you to use APO, then you know that neither one understands both. And that is a problem! Because you certainly don't want the knowledge (or lack thereof) of your adviser drive your use of SAP's Sales & Operations Planning.

I agree with the ERP proponents that, without a good basic data setup in ERP, any APO planning process is sub-optimized. So if your company has bought APO, you should make sure that your data basis in ERP is sound before you go use DP or SNP. That is mainly because your history (consumptions, sales etc.) is collected in an info structure in ERP and then loaded into an info cube in BI from where it can be used for Advanced Planning in Demand Planning in APO.

If your company did not make an investment in APO yet, it is an easy sell for the adviser to convince you to make use of ERP's S&OP (granted they know how it works). But beware! there is a lot of potential for a false setup that you will have a very hard time with later... especially when your company thinks about getting APO later. And they should, because in the long run and after getting more and more functions inside of SAP, APO should be the system of choice for your demand planning, distribution planning, production planning and procurement planning.

And if you don't set up your ERP S&OP with APO in mind, you will have a very hard time to make the switch later!

And if your adviser doesn't know APO, you can not setup your ERP S&OP with APO in mind!

Just as an example: in APO the Planner (an object) is independent of the location (plant or DC) whereas the MRP Controller in ERP is plant specific. So the product portfolio design should be setup with this in mind.

Also, in APO there are Characteristics Value Combinations. These are essentially the Planning Hierarchies used in ERP. You really don't want to redesign all that later.

Yes! You need to use what you have today. But! You will also have to prepare for the future. You can not ignore and dismiss what's possible for you tomorrow... just because your consultant doesn't know about it. Don't let anybody tell you that you are not ready for APO. It's like they sell you a Porsche and don't let you drive past second gear.

The question is how do you get to a good plan in S&OP. For those of you whose company has purchased SAP software, the speaker should lay out good practices (if not the best) and give you valuable insight on how to best use that tool - SAP. And as we all know SAP software is comprised of an S&OP tool in its ERP version but they also sell advanced planning tools with APO. Now, if you get an adviser who tells you to use ERP or another one who tells you to use APO, then you know that neither one understands both. And that is a problem! Because you certainly don't want the knowledge (or lack thereof) of your adviser drive your use of SAP's Sales & Operations Planning.

I agree with the ERP proponents that, without a good basic data setup in ERP, any APO planning process is sub-optimized. So if your company has bought APO, you should make sure that your data basis in ERP is sound before you go use DP or SNP. That is mainly because your history (consumptions, sales etc.) is collected in an info structure in ERP and then loaded into an info cube in BI from where it can be used for Advanced Planning in Demand Planning in APO.

If your company did not make an investment in APO yet, it is an easy sell for the adviser to convince you to make use of ERP's S&OP (granted they know how it works). But beware! there is a lot of potential for a false setup that you will have a very hard time with later... especially when your company thinks about getting APO later. And they should, because in the long run and after getting more and more functions inside of SAP, APO should be the system of choice for your demand planning, distribution planning, production planning and procurement planning.

And if you don't set up your ERP S&OP with APO in mind, you will have a very hard time to make the switch later!

And if your adviser doesn't know APO, you can not setup your ERP S&OP with APO in mind!

Just as an example: in APO the Planner (an object) is independent of the location (plant or DC) whereas the MRP Controller in ERP is plant specific. So the product portfolio design should be setup with this in mind.

Also, in APO there are Characteristics Value Combinations. These are essentially the Planning Hierarchies used in ERP. You really don't want to redesign all that later.

Yes! You need to use what you have today. But! You will also have to prepare for the future. You can not ignore and dismiss what's possible for you tomorrow... just because your consultant doesn't know about it. Don't let anybody tell you that you are not ready for APO. It's like they sell you a Porsche and don't let you drive past second gear.

Wednesday, December 5, 2012

Factory Physics and its possible application in SAP - variability

In previous posts I talked about using science in supply chain optimization. The science I am talking about is often rooted in Factory Physics (based on the great work of Mark Spearman and Wallace Hopp). There are many more, but the three most basic principles in Factory Physics are:

1. Little's Law, which describes working capital performance (WIP = cycle time * throughput)

2. the VUT Equation, which relates capacity, variability and time buffers (CT(q) = V * U *t) and is vital to understand costing implications

3. Variance of Lead Time Demand, which drives inventory and performance (sigma2 = Lead Time sigma2D + Demand Sigma2LT)

These formulas don't need derivation or mathematical explanations, but they describe some basic concepts which we can relate to as we define where we are standing and, maybe even more important, where we want to go in our efforts to optimize our SAP supply chain.

This blog deals with the second of these principles, the VUT formula or Kingman's equation

Variability is an unavoidable fact of life that is best managed through understanding the tradeoffs it presents. Variability is a double-edged sword—it can be good, e.g. having more than one product to offer to your customers, or variability can be bad, e.g. machine breakdowns or order cancellations, late deliveries from your vendors and large differences between forecast and actual sales.

To manage variability we take two steps:

- First, determine the amount of good variability that allows you to stay competitive

- second, use the right combination of buffers - inventory, time, capacity - and take action to reduce it.

As we all know, we can not set demand levels or product offerings at will. But we can look at relationships and their implications (e.g. by use of the VUT formula) and use practical buffer management strategies to get the best possible performance under the given circumstances and external factors. The key to success is understanding the effects of variability on your value stream and managing the trade-offs to your advantage.

To get a better understanding and to gain visibility I suggest to map your operations in an SAP value stream diagram (I have shown examples of the SAP value stream in other blog articles. It is a conventional value stream map that includes information like customizing and basic data settings in SAP). Any value stream is composed of demand and transformation (where transformation breaks down into stocks and flows), where the transformation, in form of stocks and flows i used to meet demand.

The most profitable situation is when demand and transformation are completely synchronized and demand is met with perfect supply in exactly that quantity of that product at that place on that time. We all know that this never happens. The difference is variability and variability is responsible for the appearance of three buffers.

This is not a bad thing - it's just the way things are. The bad things start to happen when executives and managers expect manufacturing and supply chain operations to behave differently than nature permit. The classic example is scheduling at 100% capacity utilization and expecting to be able to control performance well. Scheduling at 100% capacity only works out when there is zero variability and zero variability only happens at Christmas when the lines are down.

So to optimize your performance you can work with four things: The three buffers inventory, capacity and time and a reduction effort in variability. Now when it comes to using these parameters I want to quote the people from "factory Physics" as they talk about how a scientific basic is needed in today's supply chains:

"More and more, people are realizing that the goals of “eliminate variability” (from Six Sigma) and “reduce waste” (from Lean Manufacturing) are admirable goals but only state the obvious. If “eliminate variability,” is used to mean achieve zero variability, it is an impossible goal. If one accepts that zero variability is not possible so the mantra is changed to “reduce variability,” there still is no good description of what is a reasonable level of variability—as described earlier, some variability is bad and some is good. In the classic Lean Manufacturing approach, “reduce waste” is like saying, “Do the right thing.” It sounds great but doesn’t provide much direction."

I agree that we need to do more than just saying: "let's make things better!". In Factory Physics the answer to how to best optimize buffers and reduce variability is Kingman's equation. The VUT equation states that the cycle time in queue (in front of a production line or the inventory in front of a customer in the DC) is the product of a variability factor(V), times a utilization factor(U), times the effective process time(T).

The VUT is only an approximation but it gives an insight into the relationship of the three buffers and variability. It helps developing an intuition for managers to make better decisions. As an example: The combination of reducing inventory, doing nothing about variability, and expecting on-time delivery to improve or stay the same is a recipe for trouble. I've talked many times about the "unscientific inventory reduction" that some supply chain optimizers suggest. It's a prime example of where optimization projects do not produce results! With a good understanding of Factory Physics principles, your intuition would tell you not to approach inventory reduction goals by just mandating reduced inventory levels. You would accept the goal and then use your understanding of Factory Physics principles to determine what is required to achieve reduced inventory levels and direct your organization on how to proceed most quickly to achieve the inventory reduction goals with no loss in on-time delivery performance.

From Factory Physics: "The VUT equation is very useful since it describes the relationship of the three buffers in succinct form. If we want to have a low time buffer, then either V or U must be small. If V is not small, then U will have to be small. This means that if we have variability and want to have a small time buffer, we will need to have a large capacity buffer in order to keep U small.

Example: If you are constantly making schedule changes because you allow customers to make changes to their orders at any time, you should also have plenty of extra capacity available or be prepared to ship orders late. What about inventory?

For WIP we can use Little’s Law and get, WIP = CT x TH = (VUT) x TH. So to keep the inventory (WIP) buffer low we will also have to have a large capacity buffer in the presence of high variability. The VUT Equation combined with Little’s Law shows us that high variability at highly utilized work centers results in both a large time buffer and a large inventory buffer.

.. Example: What if we force WIP to be low? Managers do this all the time by limiting how much WIP is allowed in the system through use of pull systems such as kanban or CONWIP. If the VUT equation is to hold, something has to give. If variability is not reduced and process time is not decreased then U will go down with less WIP in the system. The only way for U to go down is for the throughput to go down. This is exactly what happens in manufacturing plants that are overzealous about reducing WIP. As discussed, such plants go beyond lean and become anorexic. WIP and cycle time will come down but so will output of the plant if variability is not reduced. So if you are making management decisions and you are focusing on reducing WIP, make sure you understand how much WIP is needed to maintain maximum throughput given the variability levels in your operations."

There is a lot of talk out there about the agile supply chain, the demand driven supply chain, real-time response and the lean, waste-less supply chain. i agree wholeheartedly that these are things we need to actualize with tools and functions SAP software provides us with, but look at the big picture and reference your actions to a framework that is based on a solid (scientific) basis. John F. Kennedy once said: “…be aware of the danger—but recognize the opportunity.". All too often you find yourself in an optimization project where you are beeing told about an opportunity in pursuit of better performance but the dangers are irresponsibly ignored.

If you want to be agile/demand driven/real-time, you are stipulating that you require a very small time buffer and typically executives want this fast response with little or no inventory. If you attempt to have a very small time buffer, very little inventory, and you do not reduce variability, you will need a large increase in your capacity buffer. A large capacity buffer is typically very expensive. If you do not add the necessary capacity buffer, do nothing to reduce variability, and reduce your inventory buffer, the time buffer will increase. This means longer response times, reduction in on-time delivery performance and is typically also very expensive in terms of lost customers.

to sum it up I want to quote Factory Physics again: "The solution to managing variability in your environment is to determine the amount of “good” variability that is required to be profitable in your market (e.g. range of demand volume, different product offerings, promised lead times, on-time delivery) and then implement and maintain the most profitable portfolio of:

.. buffers (inventory, capacity and time)

.. investment in reduction of “bad” variability (e.g. more fixtures to reduce setup times, stocking replacement parts to reduce downtime, dynamic scheduling, demand shaping).

Too often, executives and managers embark on great challenges or slogan-based initiatives to improve performance without a good understanding of the potential consequences of their actions. For you to be successful as an executive or manager of a manufacturing or supply chain operation, it is vital that you understand these fundamental relationships of Factory Physics principles and manage the tradeoffs proactively."

Now what does all of this have to do with your SAP supply chain? A lot. I am pleading for the use of a scientific basis before ANY optimization effort - whether it is the use of consumption based planning strategies to reduce inventory or the implementation of eKanban and MF50 scheduling to achieve 'pull' - , otherwise you might waste your time, or even worse, spend a ton of money on advisers who sell you their unscientific methodology no matter what your situation is... and ignore variability!

Variability is an unavoidable fact of life that is best managed through understanding the tradeoffs it presents. Variability is a double-edged sword—it can be good, e.g. having more than one product to offer to your customers, or variability can be bad, e.g. machine breakdowns or order cancellations, late deliveries from your vendors and large differences between forecast and actual sales.

To manage variability we take two steps:

- First, determine the amount of good variability that allows you to stay competitive

- second, use the right combination of buffers - inventory, time, capacity - and take action to reduce it.

As we all know, we can not set demand levels or product offerings at will. But we can look at relationships and their implications (e.g. by use of the VUT formula) and use practical buffer management strategies to get the best possible performance under the given circumstances and external factors. The key to success is understanding the effects of variability on your value stream and managing the trade-offs to your advantage.

To get a better understanding and to gain visibility I suggest to map your operations in an SAP value stream diagram (I have shown examples of the SAP value stream in other blog articles. It is a conventional value stream map that includes information like customizing and basic data settings in SAP). Any value stream is composed of demand and transformation (where transformation breaks down into stocks and flows), where the transformation, in form of stocks and flows i used to meet demand.

This is not a bad thing - it's just the way things are. The bad things start to happen when executives and managers expect manufacturing and supply chain operations to behave differently than nature permit. The classic example is scheduling at 100% capacity utilization and expecting to be able to control performance well. Scheduling at 100% capacity only works out when there is zero variability and zero variability only happens at Christmas when the lines are down.

So to optimize your performance you can work with four things: The three buffers inventory, capacity and time and a reduction effort in variability. Now when it comes to using these parameters I want to quote the people from "factory Physics" as they talk about how a scientific basic is needed in today's supply chains:

"More and more, people are realizing that the goals of “eliminate variability” (from Six Sigma) and “reduce waste” (from Lean Manufacturing) are admirable goals but only state the obvious. If “eliminate variability,” is used to mean achieve zero variability, it is an impossible goal. If one accepts that zero variability is not possible so the mantra is changed to “reduce variability,” there still is no good description of what is a reasonable level of variability—as described earlier, some variability is bad and some is good. In the classic Lean Manufacturing approach, “reduce waste” is like saying, “Do the right thing.” It sounds great but doesn’t provide much direction."

I agree that we need to do more than just saying: "let's make things better!". In Factory Physics the answer to how to best optimize buffers and reduce variability is Kingman's equation. The VUT equation states that the cycle time in queue (in front of a production line or the inventory in front of a customer in the DC) is the product of a variability factor(V), times a utilization factor(U), times the effective process time(T).

The VUT is only an approximation but it gives an insight into the relationship of the three buffers and variability. It helps developing an intuition for managers to make better decisions. As an example: The combination of reducing inventory, doing nothing about variability, and expecting on-time delivery to improve or stay the same is a recipe for trouble. I've talked many times about the "unscientific inventory reduction" that some supply chain optimizers suggest. It's a prime example of where optimization projects do not produce results! With a good understanding of Factory Physics principles, your intuition would tell you not to approach inventory reduction goals by just mandating reduced inventory levels. You would accept the goal and then use your understanding of Factory Physics principles to determine what is required to achieve reduced inventory levels and direct your organization on how to proceed most quickly to achieve the inventory reduction goals with no loss in on-time delivery performance.

From Factory Physics: "The VUT equation is very useful since it describes the relationship of the three buffers in succinct form. If we want to have a low time buffer, then either V or U must be small. If V is not small, then U will have to be small. This means that if we have variability and want to have a small time buffer, we will need to have a large capacity buffer in order to keep U small.

Example: If you are constantly making schedule changes because you allow customers to make changes to their orders at any time, you should also have plenty of extra capacity available or be prepared to ship orders late. What about inventory?

For WIP we can use Little’s Law and get, WIP = CT x TH = (VUT) x TH. So to keep the inventory (WIP) buffer low we will also have to have a large capacity buffer in the presence of high variability. The VUT Equation combined with Little’s Law shows us that high variability at highly utilized work centers results in both a large time buffer and a large inventory buffer.

.. Example: What if we force WIP to be low? Managers do this all the time by limiting how much WIP is allowed in the system through use of pull systems such as kanban or CONWIP. If the VUT equation is to hold, something has to give. If variability is not reduced and process time is not decreased then U will go down with less WIP in the system. The only way for U to go down is for the throughput to go down. This is exactly what happens in manufacturing plants that are overzealous about reducing WIP. As discussed, such plants go beyond lean and become anorexic. WIP and cycle time will come down but so will output of the plant if variability is not reduced. So if you are making management decisions and you are focusing on reducing WIP, make sure you understand how much WIP is needed to maintain maximum throughput given the variability levels in your operations."

There is a lot of talk out there about the agile supply chain, the demand driven supply chain, real-time response and the lean, waste-less supply chain. i agree wholeheartedly that these are things we need to actualize with tools and functions SAP software provides us with, but look at the big picture and reference your actions to a framework that is based on a solid (scientific) basis. John F. Kennedy once said: “…be aware of the danger—but recognize the opportunity.". All too often you find yourself in an optimization project where you are beeing told about an opportunity in pursuit of better performance but the dangers are irresponsibly ignored.

If you want to be agile/demand driven/real-time, you are stipulating that you require a very small time buffer and typically executives want this fast response with little or no inventory. If you attempt to have a very small time buffer, very little inventory, and you do not reduce variability, you will need a large increase in your capacity buffer. A large capacity buffer is typically very expensive. If you do not add the necessary capacity buffer, do nothing to reduce variability, and reduce your inventory buffer, the time buffer will increase. This means longer response times, reduction in on-time delivery performance and is typically also very expensive in terms of lost customers.

to sum it up I want to quote Factory Physics again: "The solution to managing variability in your environment is to determine the amount of “good” variability that is required to be profitable in your market (e.g. range of demand volume, different product offerings, promised lead times, on-time delivery) and then implement and maintain the most profitable portfolio of:

.. buffers (inventory, capacity and time)

.. investment in reduction of “bad” variability (e.g. more fixtures to reduce setup times, stocking replacement parts to reduce downtime, dynamic scheduling, demand shaping).

Too often, executives and managers embark on great challenges or slogan-based initiatives to improve performance without a good understanding of the potential consequences of their actions. For you to be successful as an executive or manager of a manufacturing or supply chain operation, it is vital that you understand these fundamental relationships of Factory Physics principles and manage the tradeoffs proactively."

Now what does all of this have to do with your SAP supply chain? A lot. I am pleading for the use of a scientific basis before ANY optimization effort - whether it is the use of consumption based planning strategies to reduce inventory or the implementation of eKanban and MF50 scheduling to achieve 'pull' - , otherwise you might waste your time, or even worse, spend a ton of money on advisers who sell you their unscientific methodology no matter what your situation is... and ignore variability!

Tuesday, December 4, 2012

what it means to optimize an SAP supply chain

there are quite some different opinions out there about what an effort to optimize the SAP supply chain actually means. In my personal opinion, a process optimization or improvement is a precursor or a by-product of an SAP supply chain optimization... and not the primary goal. Of course things will have to get better when we optimize but in this case, the use of the tool should be improved. And that means:

- a better understanding on how SAP functionality works

- a better understanding about what options are available in SAP

- better use of the SAP system to support the optimized process

- more automation

If we plot this on a matrix, we can see that the process optimization should come first - to improve on your business process - and the SAP supply chain optimization should come afterwards - to have the tool, SAP software, support the optimized processes in the most automated and efficient way.

when I visit customers, I usually see a solid process, highly skilled planners, buyers and schedulers, a very good management team and a company that works very well. And if the aforementioned would not be true, I doubt that that company would still be in business. Come on SAP consultant! Do you really think you can improve your customer's process? the way they have been doing business for years... successfully! or are you better suited helping them to get it done better using SAP as a tool? to get the most out of the available functionality? I think what is needed here, is an adviser who looks at the process and matches the right functions in SAP so that the process runs more efficient and more automated.

Almost always I see a good business running with a great degree of supply chain excellence .. but the question most likely is: "How hard is it for you - and how much manual effort does it take you - to get there?"

- a better understanding on how SAP functionality works

- a better understanding about what options are available in SAP

- better use of the SAP system to support the optimized process

- more automation

If we plot this on a matrix, we can see that the process optimization should come first - to improve on your business process - and the SAP supply chain optimization should come afterwards - to have the tool, SAP software, support the optimized processes in the most automated and efficient way.

when I visit customers, I usually see a solid process, highly skilled planners, buyers and schedulers, a very good management team and a company that works very well. And if the aforementioned would not be true, I doubt that that company would still be in business. Come on SAP consultant! Do you really think you can improve your customer's process? the way they have been doing business for years... successfully! or are you better suited helping them to get it done better using SAP as a tool? to get the most out of the available functionality? I think what is needed here, is an adviser who looks at the process and matches the right functions in SAP so that the process runs more efficient and more automated.

Almost always I see a good business running with a great degree of supply chain excellence .. but the question most likely is: "How hard is it for you - and how much manual effort does it take you - to get there?"

Saturday, December 1, 2012

Living in Tribeca...

It seems to me that over the last 5 years I did not spend a lot of time at home. In fact, looking into it, I spent about 80% of my time travelling. That KPI, I figured, stimulates me to make a point of spending more time at home. After all I live in Tribeca, one of the most featured neighborhoods in movies and books and destination to many tourists visiting New York.

Tribeca stands for TRIangle BElow CAnal street and is a historic neighborhood where, back in the days, most of those loft buildings served as giant refrigerators to store eggs and butter. Then, in the sixties, it went through its own dark ages. The building on the corner of West Broadway and Chambers, which today houses the Cosmopolitan Hotel, served as a halfway house and a place that convicted felons, who were done serving their time, used as a stepping stone to get back into society. Shootouts on West Broadway were as regular as were muggings and even murders.

In the late 70s and 80s the artists moved in, using all those lofty spaces for their studios and Tribeca became a hip spot that not a lot of people knew about. When I moved into the hood in 1997 it was still a deserted place to an onlooker, but it was a great community to the people who lived here. At night you would walk into the Odeon and there were familiar faces everywhere. The 500 feet from my apartment building to Morgans Market, the deli, took me about 30 minutes because I ran into at least 3 friends and neighbors. Everybody in the building would know everybody else who was living here and having my plants watered or the fish fed while I was traveling, did not require the hiring of a personal assistant.

Robert DeNiro had moved into the neighborhood and attracted a lot of his celebrity friends. Tribeca became a place where the hip and famous could live amongst us mere mortal fellow Tribecans without the fear of being stalked or asked for autographs. There was a time when almost the entire Sopranos crew would hang out every Wednesday night and 'Jimmy' Gandolfini would buy you a Jaeger shot while Michael Imperioli talked about how he is bummed out that he will eventually have to move to LA and leave his favorite place to live behind. Robert DeNiro's son ran a bar (more or less) and JFK junior was a regular sight at Bubby's talking to everybody there.

For a while there was a lot of activity on Reade Street. On Holidays or Sundays in July and August the fire department would open up the fire hydrants and that old cliche of children running down the street playing in the cooling water fountains became a reality - only this time it was the adults. On one occasion - right after a Soccer World Cup - we closed down the street, built a soccer field and had a two day tournament going on with an Oktoberfest on the side. Life was good in Tribeca. It was like a small village in the big city.

Then came 9/11. At first, the community became even tighter but in the long run this was a big change - of course! A lot of people moved out and then a lot of people moved in. Today I am sitting at the Cosmopolitan Cafe - as I am writing this - and look out onto a huge construction site (the Chambers Street Water project), people walking by at a rate of approximately 4 per second and there is a stroller invasion that looks for comparison.

There were many changes in Tribeca but the most obvious is the stroller invasion. Don't get me wrong: I love kids, but do I have to duck and dodge through foot traffic to not get rolled over and seriously injured by a horde of very aggresively pushing mothers? Brunch at Blaue Gans on Sunday becomes a kindergarden affair and where there was an adult playground (I am talking about restaurants or watering holes) on every corner 10 years ago, there are kiddy gyms, kids wellness centers, kids party houses and kids entertainment palazzos lined up - 5 in a row - right opposite the entrance to my building.

I am not bitter - no - I embrace the injection of youth and I know that things will always change in New York. But I do get a little nostalgic when I think about what great neighborhood this was - for me! and I realize what's great for me might not be so great for someone else.

Now that I am back here and enjoy being home again, I still love Tribeca. It still has that energy and feel that is hard to explain. But it is different; not better or worse. Just different. And we miss a few... unfortunately we lost some of the best; the ones who were a big part of making what Tribeca was all about. RIP Ralph Cummings and Angelo DiBari. You are being missed.

So today I will explore the new Tribeca. I will go to Whole Foods and buy groceries that will spoil in my fridge... because dinner at Ecco, Blaue Gans, Edwards or the Odeon is way too good to pass on the opportunity to go out to eat and meet people. I will walk around to see what's new, but rest assured, I will turn around before I get north of Canal Street. I will pass by Puffys and the Reade Street Pub because I need to make sure that I don't miss the Saturday afternoon action. And I will certainly run into a few friends and neighbors - maybe not into Kevin Spacey but maybe I see Steve Nash or that guy on 'Breaking Bad'.

Maybe it's not that different after all. In any case: it's good to be back!

Tribeca stands for TRIangle BElow CAnal street and is a historic neighborhood where, back in the days, most of those loft buildings served as giant refrigerators to store eggs and butter. Then, in the sixties, it went through its own dark ages. The building on the corner of West Broadway and Chambers, which today houses the Cosmopolitan Hotel, served as a halfway house and a place that convicted felons, who were done serving their time, used as a stepping stone to get back into society. Shootouts on West Broadway were as regular as were muggings and even murders.

In the late 70s and 80s the artists moved in, using all those lofty spaces for their studios and Tribeca became a hip spot that not a lot of people knew about. When I moved into the hood in 1997 it was still a deserted place to an onlooker, but it was a great community to the people who lived here. At night you would walk into the Odeon and there were familiar faces everywhere. The 500 feet from my apartment building to Morgans Market, the deli, took me about 30 minutes because I ran into at least 3 friends and neighbors. Everybody in the building would know everybody else who was living here and having my plants watered or the fish fed while I was traveling, did not require the hiring of a personal assistant.

Robert DeNiro had moved into the neighborhood and attracted a lot of his celebrity friends. Tribeca became a place where the hip and famous could live amongst us mere mortal fellow Tribecans without the fear of being stalked or asked for autographs. There was a time when almost the entire Sopranos crew would hang out every Wednesday night and 'Jimmy' Gandolfini would buy you a Jaeger shot while Michael Imperioli talked about how he is bummed out that he will eventually have to move to LA and leave his favorite place to live behind. Robert DeNiro's son ran a bar (more or less) and JFK junior was a regular sight at Bubby's talking to everybody there.

For a while there was a lot of activity on Reade Street. On Holidays or Sundays in July and August the fire department would open up the fire hydrants and that old cliche of children running down the street playing in the cooling water fountains became a reality - only this time it was the adults. On one occasion - right after a Soccer World Cup - we closed down the street, built a soccer field and had a two day tournament going on with an Oktoberfest on the side. Life was good in Tribeca. It was like a small village in the big city.

Then came 9/11. At first, the community became even tighter but in the long run this was a big change - of course! A lot of people moved out and then a lot of people moved in. Today I am sitting at the Cosmopolitan Cafe - as I am writing this - and look out onto a huge construction site (the Chambers Street Water project), people walking by at a rate of approximately 4 per second and there is a stroller invasion that looks for comparison.

There were many changes in Tribeca but the most obvious is the stroller invasion. Don't get me wrong: I love kids, but do I have to duck and dodge through foot traffic to not get rolled over and seriously injured by a horde of very aggresively pushing mothers? Brunch at Blaue Gans on Sunday becomes a kindergarden affair and where there was an adult playground (I am talking about restaurants or watering holes) on every corner 10 years ago, there are kiddy gyms, kids wellness centers, kids party houses and kids entertainment palazzos lined up - 5 in a row - right opposite the entrance to my building.

I am not bitter - no - I embrace the injection of youth and I know that things will always change in New York. But I do get a little nostalgic when I think about what great neighborhood this was - for me! and I realize what's great for me might not be so great for someone else.

Now that I am back here and enjoy being home again, I still love Tribeca. It still has that energy and feel that is hard to explain. But it is different; not better or worse. Just different. And we miss a few... unfortunately we lost some of the best; the ones who were a big part of making what Tribeca was all about. RIP Ralph Cummings and Angelo DiBari. You are being missed.

So today I will explore the new Tribeca. I will go to Whole Foods and buy groceries that will spoil in my fridge... because dinner at Ecco, Blaue Gans, Edwards or the Odeon is way too good to pass on the opportunity to go out to eat and meet people. I will walk around to see what's new, but rest assured, I will turn around before I get north of Canal Street. I will pass by Puffys and the Reade Street Pub because I need to make sure that I don't miss the Saturday afternoon action. And I will certainly run into a few friends and neighbors - maybe not into Kevin Spacey but maybe I see Steve Nash or that guy on 'Breaking Bad'.

Maybe it's not that different after all. In any case: it's good to be back!

Monday, November 26, 2012

Policy setting as the ultimate tool to optimize the SAP supply chain

In my personal opinion policy setting is at the heart of managing a supply chain. A policy is a set of basic data options that drive a strategy previously defined. PD (plan on demand; the MRP type on the first MRP screen in the material master) is not a policy, but with a range of coverage profile, an availability check that checks with replenishment lead time and a lot sizing indicator FX it becomes one. And that policy supports the strategy to replenish deterministically, maintain a dynamic safety stock which adjusts itself to changing demand, brings in the same fixed quantity every time it is ordered and if there is not enough stock, the availability check will quote availability right after the end of the replenishment lead time.

This policy might be assigned to purchased parts that are classified as 'high value, medium variability, short lead times and small in volume or size. Now there is a common understanding on how materials ought to be set up. An understanding that can be agreed to by management of sales, production and procurement; an understanding that can be communicated to every materials planner in your organization. You have defined a strategy and everybody knows what to do. Even the system, because the system is now executing to that strategy using the policy that was set. And since the world is changing, we must check periodically if the policy is still adequate for the given situation and circumstances.

This is why you should do 4 dimensional planning, where besides the parameters WHEN, HOW MUCH and WHAT PLACE, you have to add the dimension CIRCUMSTANCE. what is the situation at the time when I need 200 kg in Houston? do I have enough capacity? what's my availability situation? what season is it? what's the likely customer behavior at that time? what constraints do we have in the warehouse? in production?

now the questions arises: how can the material planners stay on top of a workload like this? For a planner who has to manage hundreds or even thousands of items, this becomes indeed a problem. And it is the reason why most planners can't adjust the right policy to the right situation at the right time. The Add-On tool MRP Monitor by SAP Consulting provides a solution. Not only does it give you all the functionality to perform an extensive analysis, bit it also allows you to store a policy - with all its basic data settings - which you can update automatically in the material master for a group of materials )e.g. the AXL segment)

Yes, it is not that easy and actually quite demanding to understand all implications of all these policies and then set them to the right situation... and adjust when the situation asks for it. But what Ernest Rutherford said about Physics is equally true for the SAP supply chain: "All of physics is either impossible or trivial. It is impossible until you understand it and then it becomes trivial"

Sunday, November 25, 2012

Isn't it time to use some Practical S(AP)cience?

"Management is in transition from an art, based only on experience, to a profession, based on an underlying structure of principles and science", wrote Jay W. Forrester in 1961 in his groundbreaking book Industrial Dynamics."... "any worthwhile human endeavor emerges first as an art. We succeed before we understand why" he continues. Then..."the development of the underlying sciences was motivated by the need to understand better the foundation on which the art rested."

Isn't it time to improve the art of SAP supply chain optimization with some science and underlying Laws and Principles to get a foundation and common understanding that we all can reference to? Most optimizers and advisers still just use their experience only and guide the user with intuition (that comes from various degrees of experience and runs the gamut from great to miserable judgement).

Other disciplines like Engineering or practicing Law would not nearly be as advanced would they still rest on the same descriptive transmittal of experience. And advancement in the art of SAP supply chain optimization we need! Wouldn't you agree? "...but without an underlying science, advancement of an art eventually reaches a plateau", Forrester claimed in 1961 and I believe his insights still hold water. He also states: "...companies believe their problems are unique. Because of the lack of a suitable fundamental point of view we fail to see how industrial experiences all deal with the same material, financial and human factors - all representing variations on the same underlying system." And... "to unify the separate facets of management, selected experiences have been recorded as 'cases' to provide a vehicle to discuss management as an interrelated system. This has been the best method available for integrating management knowledge, although it has been far from adequate."

This still holds true in 2012. Far too often people discredit ideas because they think the solution does not apply in their environment.

Forrester talked about management as a discipline that needed a scientific basis and reference framework. I am talking about managing the SAP supply chain and my perceived opinion to bring some practical science to the table that helps us to better evaluate and fine tune the supply chain and how it is run by SAP settings and functionality. Such a base of practical science would permit experiences to be translated into a common frame of reference from which they could be transferred from the past to the present or from one place to another.

Forrester has succeded in his vision to develop a science for the discipline of management. The topic has been evolving from Forrester through Donella Meadows with 'Thinking In Systems' and more recently John Sterman with his book: 'Business Dynamics: Systems Thinking and Modeling for a Complex World' (both from the MIT Sloan Faculty where Forrester also lectured). Also worth mentioning: 'The Fifth Discipline: The Art and Practice of the Learning Organization' (Senge 1990) is a book by Peter Senge (also a senior lecturer at MIT). His premise is that the fifth discipline, system thinking, combines the other four (personal mastery, mental models, building a shared vision and team learning) to manage and transform companies into learning organizations. Besides Systems and Business Dynamics Thinking (supported by causal loop and stock & flow diagrams) another science has been developed: 'Factory Physics' by Wallace Hopp and Mark Spearman is a book on scientific management of manufacturing dynamics. But the Principles, Laws and Corollaries explained in Factory Physics can easily be applied to the entire supply chain. Wallace Hopp has also written a paper - 'Supply Chain Science' - that translates the Factory Physics principles to a more broad application throughout the entire supply chain.

So its time to use these valuable insights to build a practical science framework for the art of SAP supply chain optimization. Systems Thinking will allow us to pinpoint inefficiencies, foresee the effects of a specific policy and supports good decision making (MTS or MTO? reduce inventory or increase availability? when to order and how much?). Through Systems Thinking the bullwhip effect can be avoided and we're enabled to see the forest again, in spite of all the trees. Factory Physics then strives to apply practical science to help with the definition of various policies. Using Little's Law, Kingman's equation (or VUT formula) and the Variability of Lead Time Demand, we can optimize the combination of buffer usage (time, inventory, capacity), fight variability and optimize our inventory levels for lowest stock with utmost service level performance. We now know where to place WIP buffers to execute the Theory of Constraints for better flow and we can reduce waste, for a lean supply chain, and increase flexibility, for an agile supply chain. A KPI framework can be developed which is based on meaningful and effective measures. This should move us much closer to SAP supply chain excellence than intuition and experience alone.

Everywhere I look, I see the more SAP-experienced person (usually consultants who get around many SAP installations) help the user with a new transaction here and a better lot sizing indicator there. Some consultancies develop methodologies for SAP supply chain optimization and come up with isolated goals (like an inventory reduction or a service level increase or more automation in purchasing). This is all good and experienced advisers are needed to help making the supply chain better. But it is only a small step to the ultimate goal of supply chain excellence. How many optimization projects fail to produce the promised results? We have reached that plateau. Lets improve on the 'art' with the application of practical science and engage in optimization projects that have a solid basis for measurable, positive results as we deal with the complexity of a modern supply chain using an integrated, holistic and factual approach.

John Sterman's Business Dynamics is an excellent reference for the building of models. Business Dynamics By Sterman, John (Google Affiliate Ad)

Saturday, November 24, 2012

Air travel in modern times...

I never flew in the 60s or 70s, but I hear it was a fun thing to do and had a lot of glamour and excitement to it. When I started going on trips that required air travel in the 80s, it was still something I really looked forward to and enjoyed greatly, while I was in the air. In the early 90s I joined the frequent flyer clubs and from then on it was one of my favorite things to do, getting preferred treatment all the way and collecting miles for free trips and upgrades into First Class. The business of supply chain optimization around the world was fun and exciting and not stressful at all.

Fast forward to yesterday: I'm glad its over! Even though I was flying Business First, I did not enjoy yesterdays flight from FRA to EWR. I even dread these things now. I really don't want to get into details - since I know that everybody knows what I am talking about - but flying is not enjoyable or exciting or glamorous anymore.Period.

Just the night before, I saw on TV how the airline industry is supposed to get revived by the Dreamliner, an airplane that Jeff Smisek from United calls the "worlds leading airplane". He talks about the fantastic colors and lighting inside the cabin, the windows darken and lighten by a push of a button and in the bathroom a single button lowers the lid and flushes the toilet at the same time. Wonderful! But the seats are no different! One of the commentators: "you still have only 17 inches to your ass to fly 17 hours to Tokyo, crammed with people left and right to you". Who cares about the lighting when the only thing you have to do on an airplane is staying in your seat? And no one even cares about that... when they configure the seating charts on the new planes.

I am at a point where the only thing that I want to do on an airplane is to sleep. Melatonin is my weapon of choice and if an airplane manufacturer would ask me what to do to build better planes, I would ask for anything that puts me out: release some gas into the cabin that knocks everybody out after 2 minutes, hand out narcotics (legally o course) or lull me into sleep with music... anything that makes me not to experience the flight at all. Isn't that sad? That the product these airlines sell us is so bad that no one wants to experience it? Shouldn't they ask themselves: "why is everybody complaining and what can we do to have happier customers?" But customer satisfaction is very obviously not a thing that they care too much about.

Just this year Continental was taken over by United. I flew regularly on Continental since 1992 and I really don't know if it is United but this year specifically, I have experienced a sharp rise in unacceptable and inconvenient incidents on my trips. Like I said: Its not like it used to be.

On the United program they now give us frequent flyers a contingency of upgrades. Unfortunately they expire at the end of the year but, even worse, they don't just let you upgrade. It's all dependent on whether they can still make money selling the seats. Just now I tried to use one of my global upgrades, but received a message 'no seats available in front cabin'. So out of the 6 global upgrades I had "at my disposal", I have 3 left over which expire on 12/31. And that even though I flew 14 international legs in 2012. So what's the purpose?

You also receive 4 upgrades which you can use within the continental US. Every frequent flyer - whether they fly 25,000 miles a year or 150,000 - will get domestic upgrades. For a flyer like me, who travels between 100,000 and 130,000 miles a year, this means 4 flights in business class and about 35 in coach. Back in the good old "Continental" days, I got upgraded on 95% of my flights. And please don't get me wrong. I don't want to disrespect less frequent travelers, but I wouldn't mind sitting in coach on 2 or 3 round trips a year. However, if you sit on a plane twice a week and you have to work right off the flight, it is a very tiring experience.

enough complaints: I am home now and won't have to travel for 10 days. Yeeha! I am really excited and happy...

...and by the way: George Clooney wouldn't stand a chance accumulating 10 million miles.

Fast forward to yesterday: I'm glad its over! Even though I was flying Business First, I did not enjoy yesterdays flight from FRA to EWR. I even dread these things now. I really don't want to get into details - since I know that everybody knows what I am talking about - but flying is not enjoyable or exciting or glamorous anymore.Period.

Just the night before, I saw on TV how the airline industry is supposed to get revived by the Dreamliner, an airplane that Jeff Smisek from United calls the "worlds leading airplane". He talks about the fantastic colors and lighting inside the cabin, the windows darken and lighten by a push of a button and in the bathroom a single button lowers the lid and flushes the toilet at the same time. Wonderful! But the seats are no different! One of the commentators: "you still have only 17 inches to your ass to fly 17 hours to Tokyo, crammed with people left and right to you". Who cares about the lighting when the only thing you have to do on an airplane is staying in your seat? And no one even cares about that... when they configure the seating charts on the new planes.

I am at a point where the only thing that I want to do on an airplane is to sleep. Melatonin is my weapon of choice and if an airplane manufacturer would ask me what to do to build better planes, I would ask for anything that puts me out: release some gas into the cabin that knocks everybody out after 2 minutes, hand out narcotics (legally o course) or lull me into sleep with music... anything that makes me not to experience the flight at all. Isn't that sad? That the product these airlines sell us is so bad that no one wants to experience it? Shouldn't they ask themselves: "why is everybody complaining and what can we do to have happier customers?" But customer satisfaction is very obviously not a thing that they care too much about.

Just this year Continental was taken over by United. I flew regularly on Continental since 1992 and I really don't know if it is United but this year specifically, I have experienced a sharp rise in unacceptable and inconvenient incidents on my trips. Like I said: Its not like it used to be.

On the United program they now give us frequent flyers a contingency of upgrades. Unfortunately they expire at the end of the year but, even worse, they don't just let you upgrade. It's all dependent on whether they can still make money selling the seats. Just now I tried to use one of my global upgrades, but received a message 'no seats available in front cabin'. So out of the 6 global upgrades I had "at my disposal", I have 3 left over which expire on 12/31. And that even though I flew 14 international legs in 2012. So what's the purpose?

You also receive 4 upgrades which you can use within the continental US. Every frequent flyer - whether they fly 25,000 miles a year or 150,000 - will get domestic upgrades. For a flyer like me, who travels between 100,000 and 130,000 miles a year, this means 4 flights in business class and about 35 in coach. Back in the good old "Continental" days, I got upgraded on 95% of my flights. And please don't get me wrong. I don't want to disrespect less frequent travelers, but I wouldn't mind sitting in coach on 2 or 3 round trips a year. However, if you sit on a plane twice a week and you have to work right off the flight, it is a very tiring experience.

enough complaints: I am home now and won't have to travel for 10 days. Yeeha! I am really excited and happy...

...and by the way: George Clooney wouldn't stand a chance accumulating 10 million miles.

Tuesday, November 20, 2012

Inventory projections are an important part of any KPI framework... The LIS is NOT!

I hear many of you asking for future inventory projections, so you can plan supply to variable demand and end up with optimized stock levels, exceptional service levels and good availability.

I believe that this is a very valid request and inventory projections must be part of any KPI framework. But mostly I hear advisers talking about current and past inventory. In some cases a reduction is proposed, so that future inventory is less than it is now (some of these consultancies even want a percentage of the reduction). So what if you need more? Inventory optimization is about striking a balance between availability and surplus (dead stock) and should be checked against future requirements. To just look at dead stock today, does not help you to make decisions about your replenishment, planned consumption, availability and stock level in the future.

Before I go about how to plan for future, optimized stock level, I would like to talk about how NOT to go about them.

You probably heard them... They might have knocked on your door... They might have even made some money wasting your time? I am talking about the LISers. Those people unaware of SAPs new developments (and every adviser should be obliged to be up-to-date on SAP developments) , unaware of BI, BOBJ, Add-On tools or enhancements to measure, monitor and evaluate the SAP supply chain... other than by means of the LIS (the Logistics Information System)

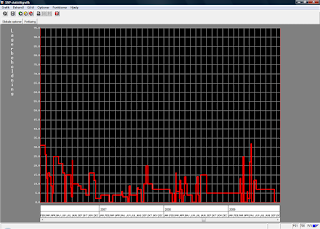

They get excited by a red line on black background or a dual classification that takes about ten minutes to call up and leaves absolutely no room for customization (and looks like crap). They promote using info structures which have no flexibility, are extremely cumbersome to fill and any query on them runs forever. They tell you that SAP does not provide support anymore because the LIS 'just works' (yeah right). But most insanely,they teach you all the tricks on how to get around and spend hours working in the LIS. Who cares?! And who wants to get around in the LIS?

So stop talking about the LIS. SAP doesn't talk about it anymore. And neither does anyone else. If this is your only play, you will not make it through the first quarter.

Future inventories are designed by using a KPI framework in a planning environment. Past consumption is important but so are future projections. Only if you put the two together you can make an assessment whether you need less or more. Availability and agility is as important nowadays as is less waste (in overproduction or excess inventory). But what was true yesterday might not be true today. The LISers look back! and back only... everybody else should use the past to build a better future... where the future should be anticipated with a vision, anticipation and foresight (none of which an LISer possesses).

Marc Hoppe and his team from SAP Consulting have developed an Inventory Cockpit that helps with exactly that. On basis of a customized Material Document Aggregation, which the LIS does not have a chance to do, the Inventory Cockpit provides a multitude of KPIs and measures to determine future inventory levels - amongst many other things.

I believe that this is a very valid request and inventory projections must be part of any KPI framework. But mostly I hear advisers talking about current and past inventory. In some cases a reduction is proposed, so that future inventory is less than it is now (some of these consultancies even want a percentage of the reduction). So what if you need more? Inventory optimization is about striking a balance between availability and surplus (dead stock) and should be checked against future requirements. To just look at dead stock today, does not help you to make decisions about your replenishment, planned consumption, availability and stock level in the future.

Before I go about how to plan for future, optimized stock level, I would like to talk about how NOT to go about them.

You probably heard them... They might have knocked on your door... They might have even made some money wasting your time? I am talking about the LISers. Those people unaware of SAPs new developments (and every adviser should be obliged to be up-to-date on SAP developments) , unaware of BI, BOBJ, Add-On tools or enhancements to measure, monitor and evaluate the SAP supply chain... other than by means of the LIS (the Logistics Information System)

They get excited by a red line on black background or a dual classification that takes about ten minutes to call up and leaves absolutely no room for customization (and looks like crap). They promote using info structures which have no flexibility, are extremely cumbersome to fill and any query on them runs forever. They tell you that SAP does not provide support anymore because the LIS 'just works' (yeah right). But most insanely,they teach you all the tricks on how to get around and spend hours working in the LIS. Who cares?! And who wants to get around in the LIS?

So stop talking about the LIS. SAP doesn't talk about it anymore. And neither does anyone else. If this is your only play, you will not make it through the first quarter.

Future inventories are designed by using a KPI framework in a planning environment. Past consumption is important but so are future projections. Only if you put the two together you can make an assessment whether you need less or more. Availability and agility is as important nowadays as is less waste (in overproduction or excess inventory). But what was true yesterday might not be true today. The LISers look back! and back only... everybody else should use the past to build a better future... where the future should be anticipated with a vision, anticipation and foresight (none of which an LISer possesses).

Marc Hoppe and his team from SAP Consulting have developed an Inventory Cockpit that helps with exactly that. On basis of a customized Material Document Aggregation, which the LIS does not have a chance to do, the Inventory Cockpit provides a multitude of KPIs and measures to determine future inventory levels - amongst many other things.

The final assembly line as the link between Sales and Production

One of my favorite customers makes appliances and components for the consumer products industry.

Today we went live with a new concept linking forecast and customer orders with a production scheduling strategy. The key phrase is "smoothing irregular demand".

Our customer's production plant receives orders from each of the networks DC's as well as direct customer orders. The DCs, of course, take the customer orders and that demand can be quite irregular. Up until now the supply chain acted quite random and planners, schedulers and sales reps had a hard time at work.

This, as I believe, was due to the "order related and oriented" process dominating fulfillment, distribution and production. A sales order from the DC was forwarded to the production plant in the same quantity and then translated individually throughout the BoM. A yellow slip followed the order from the raw material through final assembly to packaging, distribution to the DC and finally the delivery to the customer.